5 Different Types of Cargo Bars and How to Use Them

The number one priority of all transport truck drivers is safety. The second priority of all transport truck drivers is getting the cargo to its final destination undamaged. Knowing this, It makes sense to use any tool available to increase the chances of accomplishing these two priorities.

Cargo bars do exactly that!

Cargo bars, also called load bars, have been used by semi-truck and pickup drivers for years to safely secure their loads and prevent load shifts. As these drivers look for new and innovative ways to protect themselves and their cargo, a variety of different cargo bars have been developed. The following list discusses 5 of the most popular types of cargo bars and how to properly utilize them in order to improve safety.

Load Lock Bars

Load Lock Bars are a quick and easy way to secure cargo in the back of a pickup truck or semi. Each bar has a rubber foot pad that is either bolted or welded to the ends of the bar depending on your preference. These rubber pads are a crucial piece of the load lock bar because they allow both ends to be firmly secured to the walls of your vehicle.

It is important to check these pieces each time you use your cargo bar because damage to them could result in slippage. Our Load Lock Bars also feature an easy release mechanism that allows you to quickly adjust the bar to the desired height, even with bulky safety gloves on.

A variety of customization options are available for the Load Lock Bars on our website. We have sizes ranging from 50 inches all the way up to 112 inches. This range allows us to accommodate small pickups, large semi-trucks, and everything in between. Whatever size you may need, we have a load lock that can fit your specifications. Customizations for the strength of the bar are available as well.

For lighter loads, we would recommend our Aluminum Load Lock Bar because of its lightweight design. For heavier loads, our Standard Steel Load Lock Bar or our Heavy Duty Steel Load Lock Bar will get the job done. The Steel used in our heavy-duty steel load lock bar is 30% thicker than the standard model so for your heaviest loads, we would recommend the heavy-duty model.

Jack Load Bars

Jack Load Bars are slightly different from Load Lock Bars. Both bars use pressure to stabilize themselves on the sidewalls of a vehicle but Jack Load Bars use a jack to apply the pressure instead of just a release mechanism. This gives them an advantage over standard load lock bars in this area because the jack allows the user to more firmly secure the bar to the outside walls.

Users need to be careful though because putting excessive pressure on the sidewalls of a semi could cause serious damage to them. Only tighten the bar firmly enough to safely contain your cargo.

These Cargo Bars are available in both square and round versions. The rubber feet on the ends of the Jack Load Bar are 4×4 and can be welded on or bolted on depending on your preference. One question that a lot of people have with the cargo bars and load bars is Where will I store them?

Our cargo bars with jacks, make storage much easier. Two types of storage options are available depending on the bar that you purchase. We have a 2-piece jack load bar and a 3-piece jack load bar available on our site. The 2-piece version breaks down into two 48-inch pieces and the 3-piece version breaks down into three pieces around 30 inches in length.

E Track Load Bars

E Track Load Bars help you make the most out of the space in your semi. So many options are available for anyone who has an E-track system currently installed in their truck. They can be used as a normal load bar to separate loads and prevent load shift or they can be used to create multiple levels and optimize space that would normally be unusable. This makes them a versatile tool in the cargo control industry.

Each day truck drivers are limited by the amount of time they can be on the road and by how much they can haul in the back of their truck. By using our E track shoring beams you can greatly increase the amount of usable space in your truck. Maximizing the amount of product that can be moved by one truckload ultimately increases the amount of profit for a company.

E Track Shoring Beams are not only used in the back of semis. Some people use shoring beams in the back of smaller trailers and even in garages or sheds. Our wood beam sockets are perfect for creating layers in your crowded garage or trailer. E-track load bars with hoops add an extra layer of containment and are great for securing multiple boxes that may be susceptible to shifting or falling.

All of these examples speak to the versatility of the E track systems as a whole. Our E track bars range in size from 87 to 103 inches in order to fit any type of truck or trailer. We also have replacement parts for all of our E track cargo bars, that way if you damage your E track bar you can simply order another part instead of an entire bar.

Hoop Load Bars

A Hoop Load Bar is everything that a Cargo Bar or a Load Bar is except it has large metal hoops attached to it. These hoops increase the coverage area of the cargo bar and allow for even more protection against load shift. The hoops can either be welded on or bolted on depending on your preference. The bolted hoops can be removed for storage purposes. Hoops can be added to any one of the Cargo Bars or Load Bars on our website.

Hoop Load Bars are specifically designed for large boxes that are susceptible to load shift during transit. The large rectangular shape of these bars is able to contain things that normal cargo bars would not be able to safely handle. With the bolted on version of our hoop cargo bars, it is important to make sure that the hoops are properly secured.

Cargo bars with hoops are often responsible for containing heavy boxes and other objects so failure to properly secure the bolts could be catastrophic for both the driver and the cargo. Our Load Bars with hoops are available in sizes ranging from 89 to 112 inches and can be made with either standard or heavy-duty steel.

Pickup Load Bars

Whether you are a contractor transporting heavy equipment in your pickup or a soccer mom picking up groceries in your suburban, our Pickup Load Bars can make your life easier. The sturdy steel construction of our cargo bars means that you can haul heavy loads without being too heavy for everyday use.

Each bar has a simple ratcheting mechanism that makes extending and shortening easy. Our pickup Cargo Bars range in size from 50 to 73 inches. This allows us to accommodate the needs of virtually every pickup truck, compact or full-size. If you are concerned about storage be sure to check out our Pickup Cargo Bag. This bar is s great way to easily and safely store your cargo bars while you are not using them. Some assembly is required for our pickup load bars.

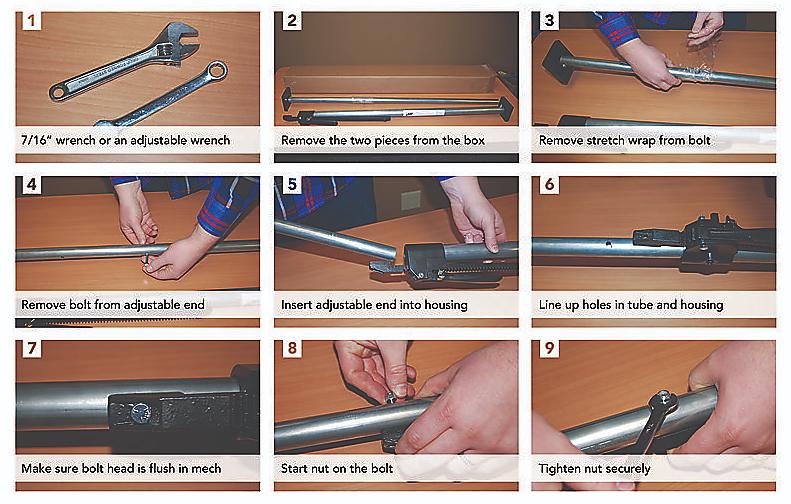

How to Assemble a Load Lock Bar

1). Find an adjustable wrench

2). Remove the two pieces from the box

3). Remove the stretch wrap from the bolt

4). Remove the bolt from the adjustable end

5). Insert the adjustable end into the ratcheting mechanism

6). Line up the holes in the tubing and the ratcheting mechanism

7). Make sure the bolt is flush in the mechanism

8). Start the nut on the bolt

9). Tighten the nut securely

Frequently Asked Cargo Bar Questions

What sizes do your cargo pickup truck bars come in? – Compact with a 50 inches to 65 inches adjustment or Full-sized with a 59 inches to 73 inches which fits most normal sized pickup truck beds.

Why are cargo bars not strength rated? – The reason behind jack bars not being strength rated is due to the variance in the different walls between trailer to trailer. As no two trailers are exactly alike in terms of strength, age, and materials used along the walls we do not provide a strength rating. If you have any questions about the strength capabilities or if it would be safe to use to secure your load give our experts a call at 800-807-5634 or by using our online contact us page. We look forward to helping you with all of your cargo securement needs.

Can cargo bars be left outside between uses? – Yes, these bars are able to be used out in the elements. We often hear of customers storing their pickup truck bars in the back of pickup truck beds in between uses. Although this may make the product more limited over several years we have heard good feedback from our long-term product owners of the durability.